Description

90° JIC Assembly with Threaded Sleeve – for 8.6 mm High-Pressure Hose

This 90° JIC assembly provides a durable, pressure-rated connection between lubrication lines and fixed components in centralized lubrication systems. Its angled configuration allows precise hose routing in confined or complex layouts while maintaining a secure, leak-resistant joint for grease or oil. The assembly combines a threaded sleeve, 90° hose stud, and JIC adapter to form a compact, corrosion-resistant interface for 8.6 mm high-pressure hose rated to 840 bar.

Assembly Includes

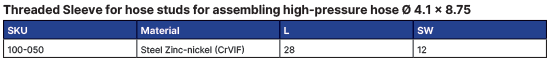

- 100-050 | Threaded Sleeve – Secures 8.6 mm hose onto the hose stud to form a pressure-rated seal.

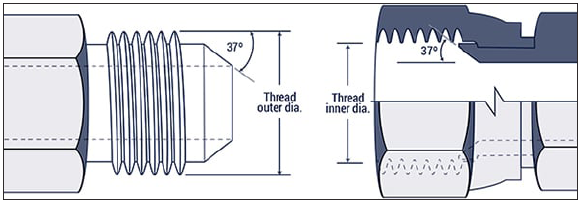

- 3511-114 | 90° JIC Hose Stud – 7/16-20 JIC 37° male flare thread for angled, high-pressure connections.

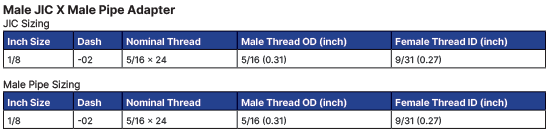

- 2404-04-02 | Male JIC × Male Pipe Adapter – Transitions from JIC 37° male flare to 1/8 NPT male pipe thread for direct integration with lubrication manifolds or junction blocks.

Material & Coating

- Threaded Sleeve and Hose Stud: Steel with Zinc-Nickel (CrVIF) coating for high corrosion resistance and long service life.

- Adapter: Steel with Clear Zinc Trivalent coating for a bright, RoHS-compliant finish.

The combined plating system provides strong corrosion protection and easy component identification during assembly.

Technical Overview

- 90° configuration for tight routing and optimized hose positioning

- Provides a leak-resistant, vibration-stable connection under load

- Suitable for centralized lubrication systems using grease or oil

- Designed for 8.6 mm high-pressure hose rated to 840 bar (12,184 psi)

Typical Applications

- Centralized grease and oil lubrication systems

- Manifold and junction block connections in space-limited layouts

- Industrial machinery, construction, and mobile equipment

Additional Information

For ordering assistance, material alternatives, or technical support, contact Lubrication Technologies at (413)-788-5823 or Contact Us Online.