Description

Straight-to-90° JIC Assembly with Threaded Sleeve – for 8.6 mm High-Pressure Hose

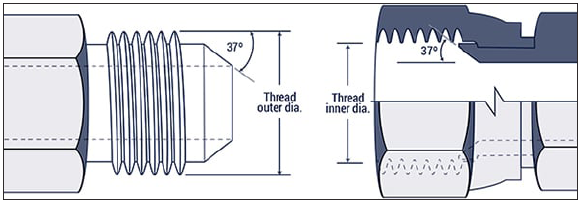

This JIC assembly provides a compact, pressure-rated connection between lubrication lines and system components in centralized lubrication systems. Its straight-to-90° configuration allows for tight routing in confined spaces while maintaining a secure, leak-resistant path for grease or oil. The assembly combines a threaded sleeve, straight hose stud, and 90° JIC adapter to create a durable, corrosion-resistant interface for 8.6 mm high-pressure hose rated to 840 bar.

Assembly Includes

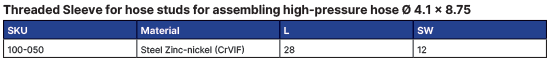

- 100-050 | Threaded Sleeve – Secures 8.6 mm hose onto the hose stud to form a pressure-rated seal.

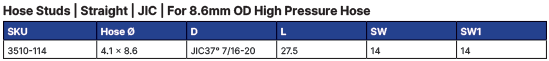

- 3510-114 | Straight JIC Hose Stud – 7/16-20 JIC 37° male flare thread for standardized high-pressure connections.

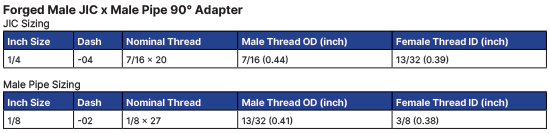

- 2501-04-02-FG | 90° Male JIC × Male Pipe Adapter – Transitions from JIC 37° male flare to 1/8 NPT male pipe thread at a right angle, simplifying hose routing in limited-space installations.

Material & Coating

- Threaded Sleeve and Hose Stud: Steel with Zinc-Nickel (CrVIF) coating for high corrosion resistance and long service life.

- Adapter: Steel with Clear Zinc Trivalent coating for a bright, RoHS-compliant finish.

Combination of coatings provides enhanced protection and visual differentiation between components.

Technical Overview

- Straight-to-90° design for compact hose routing and reduced line stress

- Provides a leak-resistant, vibration-stable connection under load

- Suitable for centralized lubrication systems using grease or oil

- Designed for 8.6 mm high-pressure hose rated to 840 bar (12,184 psi)

Typical Applications

Centralized grease and oil lubrication systems

Manifold, junction block, and enclosure connections with limited clearance

Industrial machinery, construction, and mobile equipment

Additional Information

For ordering assistance, material alternatives, or technical support, contact Lubrication Technologies at (413) 788-5823 or Contact Us Online.