Description

Compression Ferrules

Sealing rings for secure tube connections in centralized lubrication systems.

Compression ferrules, also known as sleeves or cutting rings, are used with compression nuts and fittings to create secure, leak-resistant connections in centralized lubrication systems. They are essential components for assembling tube-to-fitting joints in systems handling grease or low-viscosity oil. Commonly used in construction equipment, industrial machinery, commercial vehicles, and wheel flange lubrication setups.

Variations

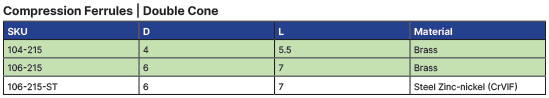

- 104-210 4mm single cone

- 104-211 4mm brass to be used in 1022-106 fitting

- 104-215 4mm brass double cone

- 106-210 6mm single cone

- 106-210-L 6mm single cone (long)

- 106-215 6mm brass double cone

- 108-210 8mm single cone

- 108-210-L 8mm single cone (long)

- 110-210 10mm single cone

- 110-210-L 10mm single cone (long)

Material & Benefits: Steel Zinc-nickel (CrVIF)

Our steel fittings feature a Zinc-nickel (CrVIF) alloy coating, electroplated directly onto the surface for superior corrosion resistance and durability. This finish combines approximately 10–15% nickel with zinc to form a hard, smooth, and long-lasting protective layer—making it an ideal alternative to traditional zinc or cadmium coatings.

Benefits of Zinc-nickel Coating

- Provides up to 10x more corrosion resistance than standard zinc

- Offers improved wear resistance for moving parts

- Withstands thermal stress better than conventional finishes

- Commonly used in automotive and aerospace applications

Additional Information

For more information about compression fittings, or to determine if this product is right for your application, contact us online or at (413) 788-5823.