Description

Hose Studs 90° for 8.6mm OD High-Pressure Hose

90° hose studs for sharp, high-pressure turns in confined lubrication system spaces.

These 90° hose studs are designed for use with 8.6mm OD high-pressure hoses in centralized lubrication systems. The right-angle design allows for tight turns and optimized hose routing in space-constrained environments while maintaining a secure, leak-resistant connection. Compatible with threaded sleeves and push locks or compression fittings, these hose studs are built for dependable operation in demanding conditions.

Most models are available with or without a groove for compatibility with push locks when required.

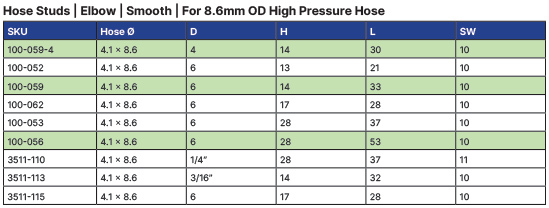

Variations

- 100-059-4 4mm - L: 30mm

- 100-052 6mm - L: 18mm

- 100-053-NUT 6mm - L: 37mm

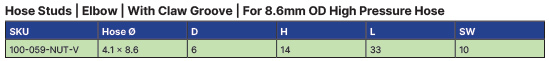

- 100-059-NUT-V 6mm - L: 33mm

- 100-056-NUT 6mm - L: 53mm

- 3511-110 1/4" - L: 35mm (For use with 100-050 screw sleeve)

- 3511-112 1/4" - L: 35mm - replaces Lincoln™ 272394 (For use with 100-050-1 screw sleeve)

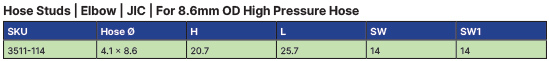

- 3511-114 JIC 37° 7/16-20 diameter - L: 25.7mm

Comparable Items

- Hose Studs 90° for 8.6mm OD High-Pressure Hose - Stainless Steel

- Hose Studs 90° for 11.3mm OD High-Pressure Hose - Steel Zinc-nickel (CrVIF)

- Hose Studs 90° for 11.3mm OD High-Pressure Hose - Stainless Steel

Material & Benefits: Steel Zinc-nickel (CrVIF)

Our steel fittings feature a Zinc-nickel (CrVIF) alloy coating, electroplated directly onto the surface for superior corrosion resistance and durability. This finish combines approximately 10–15% nickel with zinc to form a hard, smooth, and long-lasting protective layer—making it an ideal alternative to traditional zinc or cadmium coatings.

Benefits of Zinc-nickel Coating

- Provides up to 10x more corrosion resistance than standard zinc

- Offers improved wear resistance for moving parts

- Withstands thermal stress better than conventional finishes

- Commonly used in automotive and aerospace applications

Additional Information

For more information about hose studs, or to determine if this product is right for your application, contact us online or at (413) 788-5823.